Hello….hope everyone had a great Saturday. No shop time for me this Saturday but I have some fun subjects to touch on. Today was the company picnic for the company I work for ( www.fike.com ). It was a beautiful weather day here with lower 90’s and a nice breeze. They have a charity that they support year around and at the picnic they have around a dozen raffle baskets that they raffle off. This year I donated my ‘Web Clock’ that I built a couple months back. I was glad that it went over well…and someone put tickets in to win it. So that was fun for me.

Over the last week I was able to get 2/3’s of my homework done so I am well on pace to to be able to finish up the Pyle Clock except for the vine overlays and the face. Next week over Labor Day we will be out of town so no shop time next Saturday either. From a design side of things, I added a double size version of the Micro Mini Grandmother Mini Clock to the full size pattern (WW-0233). This is the Clock Kyle finished up a couple weeks ago and we have had some interest in that so now the patterns includes both. Check it out on the website. We also put a couple new projects on the website. I also worked on finishing up the Anniversary clock pattern. Sorry I’ve been dragging my feet on getting this one available. It is a little more involved since it includes 4 major projects on one pattern. I promise it will be worth the wait.

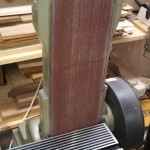

This week I’d like to talk about sanders and sanding. It is something that we all have to do to finish out our projects. I have included pictures of my weapons of choice. There are several different types, brands and options. I have my small hand sander that I use. Like with any sander you need to use them with care to not damage your work piece. I use a small sanding pad to place my work piece on but you can also use a piece of carpet or carpet padding. I also have a larger hand sander and I typically use this sitting pad up and place the work piece lightly on top. With both of these type sanders…don’t apply a lot of pressure when you use them. Let the sander do the work for you. This next one…laugh if you want…is one of my most trusted and beloved sanders. It is a piece of plywood (it was our table top when we had our radial arm saw…sand paper on the bottom) with pieces of sandpaper attached to it by using the spray glue I use for applying patterns. To use it you just lightly move your piece back and forth. I have it set up with course paper for aggressive sanding. But when I have something that I want flat and square…this is the one I most often go to. It is more work but I am old school and Dad just loved this. If by using one of the other sanding methods you get your work piece slightly out of square or rounded….this is the best recovery tool I have used. Simple and cheap also! I also have two basic shop sanders. I have a large disc sander that is heavy duty with a nice tilt table where I do a lot of my angle work. I also have a belt sander that is my quick ‘get ‘er done’ sander. This is also the sander I use for all my contour work. I have a few patterns that require rounded edges and contour sanding such as the Azure Clock and the Jet Fighters. And last but not least is the Sand Flee. This is an awesome machine and has a place in all wood shops. Be sure to watch the link I have included on it. Stephen Raffo does a great job talking about it. Bob and Stephen are very familiar faces at all the shows and great guys to talk to. I have included a few links to check out. Some talk about how to sand, some give maintenance tips and some advertise sanders. One last thing I’ll throw out. It is very important to keep your sanding belts or pads cleaned out. I just use a good gum stick. You can pick these up at any store that carries woodworking supplies. This also gives you more life out of your belts/pads.

Also this week I had a conversation with someone about finishing out the bottom of a box. There are several different things you can do to finish this and give it that perfect touch. First off you can install the small felt pads. This will lift your box slightly off the surface it sits on and helps if you have some unevenness. I place these in from the edge so they don’t show. Along this same thought process….even though I haven’t…yet…you could Flock the bottom and this would give you a nice soft bottom surface. Then there is the option of small brass feet that you just put on the corners with small nails or screws. I have used these a lot. I get these from Wildwood/Cherrytree but you can get these at hobby stores also. I actually have a pattern that includes some of these…..just went and found it. This may be a good pattern to throw up on the web-site. Look for that to be there soon.

My last subject for the week is the Shop Project I started about a year ago….the memorial fretwork pieces to honor Dad. When I went through and cleaned up the shop after Dad passed away, I gave some of the older equipment we had to my Brother Scott and bought a nice work bench cabinet. But it is very plain….so I designed fretwork for it and then got the idea to let all Dad’s friends cut out a piece for it. I handed out several patterns and got about 2/3’s of them back. I ask people to cut it out of a scrap of their favorite wood and I would turn it into a colorful memorial that would honor Dad….a big memorial to him made by his friends and displayed in his shop. It is STILL his shop…..I just use it….because of the magic that lives in those walls. Well I just came across the box of pieces last week then someone e-mailed asking about it again. So I plan on bringing some focus back to this project. If anyone is interested in being a part of this just let me know. When I get back to the shop I will take an inventory and see which pieces I still need. I have marked each piece and know who did each one and will have this marked and I plan on doing a write up on it as well….maybe get one of the mags interested in running the story on it. Dad was/still is Loved by many and one of our Icons in our discipline of woodworking.

That about does it for another week. Hope everyone has a good Sunday and your upcoming week is spectacular. Again this week please keep all of our woodworking brothers and sisters who are struggling or hurting in your prayers. Also be sure to check out our approved vendors and catch us at www.wilckenswoodworking.net and on facebook. Look for our ads in S.A.W. and Creative Woodworks & Crafts. We have several new things available right now along with ALL the old stuff. If we’ve had it…we still do. Don’t be a stranger….drop us a line to say hey….we love talking to ya. Send us pictures of what you have going so we can share those and if you’ve cut out the free Web Clock…send us pictures of that. I know several of you that have been working on it but we have received only a few pictures. Remember that the best one (voted by your peers) will receive a premium pattern. Have a great finish to your weekend and a good week next week….and as always…

Until Next Time, Keep the Saw Dust Flyin’…..

Dan